Where Control Meets Automation Precision

At UW-Stout, our Industrial Controls & Automation Engineering Lab provides students with hands-on learning opportunities to understand the intricacies of machine control and safety. Featuring power electronic trainers, hydraulic and pneumatic systems, and fluid power and mechanics, this lab teaches students how to effectively control larger machinery. The lab also includes state-of-the-art Digital Twin software from Rockwell Automation, allowing students to apply physics and motion to CAD models and run them with programmable logic controller (PLC) programs before making physical modifications. With a focus on advanced classes in human-machine interfaces (HMIs), motion control, and instrumentation, students gain the skills and confidence needed to excel in real-world engineering environments.

Degrees That Do More in This Lab

Dive Deeper Into the Industrial Controls & Automation Engineering Lab's Equipment and Software

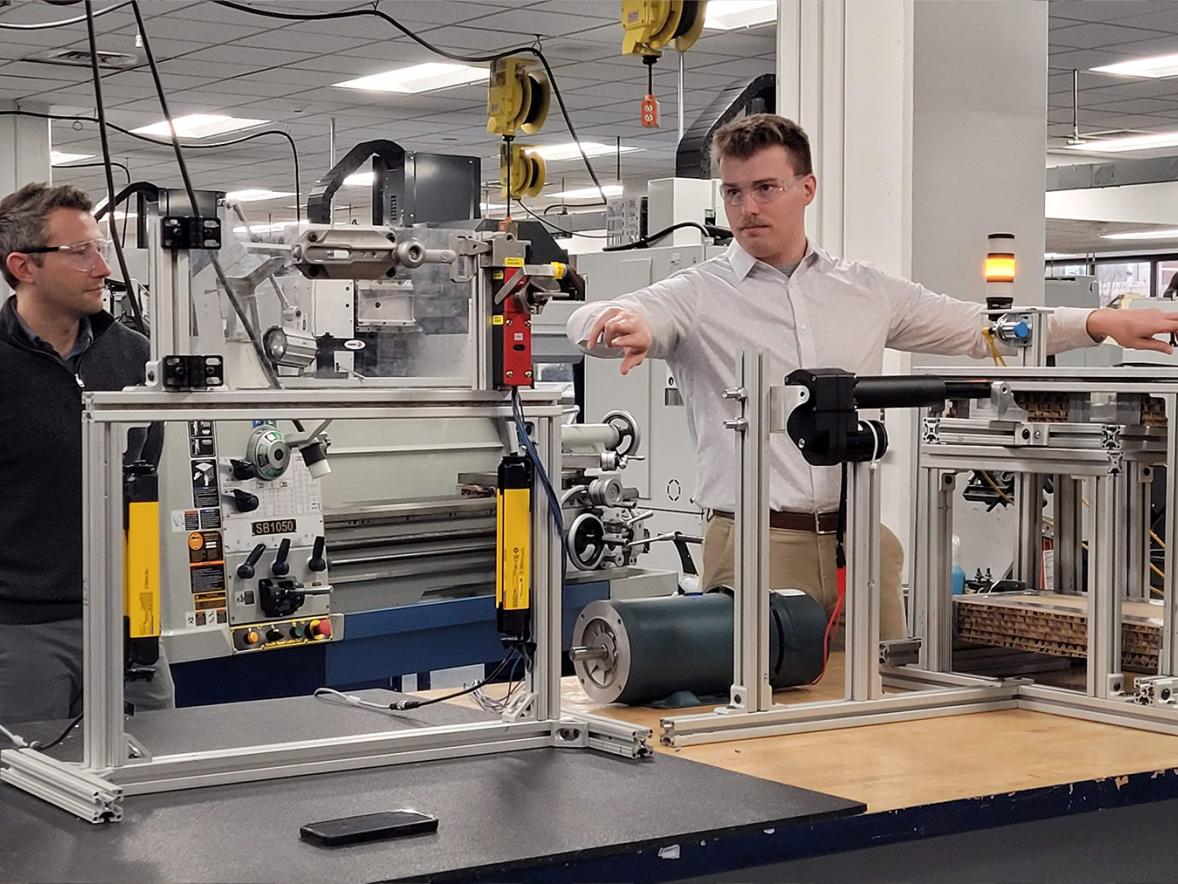

Our control trainer machinery teaches students how to manage and operate larger machinery with precision and safety. This equipment provides hands-on experience with real-world applications of machine control, allowing students to build skills in handling complex systems effectively.

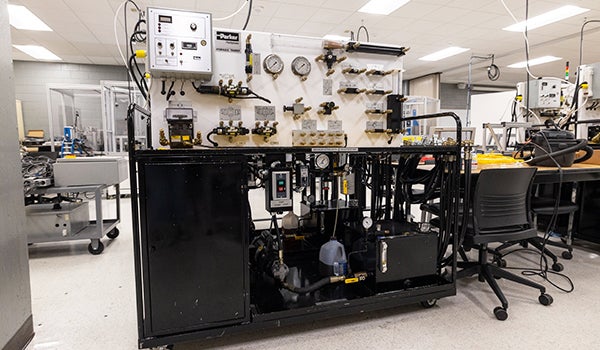

The hydraulic trainer allows students to explore the principles of hydraulics and fluid power systems through hands-on interaction with pumps, valves, and actuators. This equipment supports understanding fluid dynamics and the practical applications of hydraulic machinery in engineering.

Our power electronic trainers offer hands-on experience with power electronics, control systems, and circuit design. Students engage with real components, analyze system behaviors, and simulate real-world scenarios, developing essential skills for modern engineering careers.

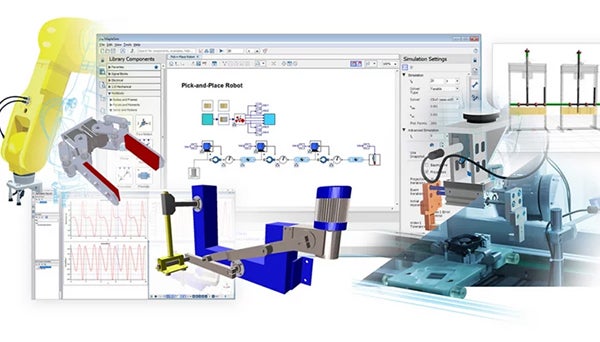

The Rockwell Automation Digital Twin Software enables students to simulate and analyze CAD models with applied physics and motion. This hands-on tool allows for testing and refining PLC programs before physical implementation, fostering essential skills in digital modeling and system optimization.