The Phoenix Challenge Competition (PCC) represents a hands-on learning experience to, “engage college-level students in creatively solving a current, industry-relevant flexographic problem which would allow them to practice and showcase their research, problem-solving, design, and print production skills. The goal is to inspire academic programs to grow and improve their level of instruction and research.”

Flexographic printing is a specific printing process that is used for the flexible packaging and label industry. It uses a flexible photopolymer plate, like a modern rubber stamp, to print and produce packagings such as bags, labels, boxes, and plastic wraps that dominate the food packaging industry.

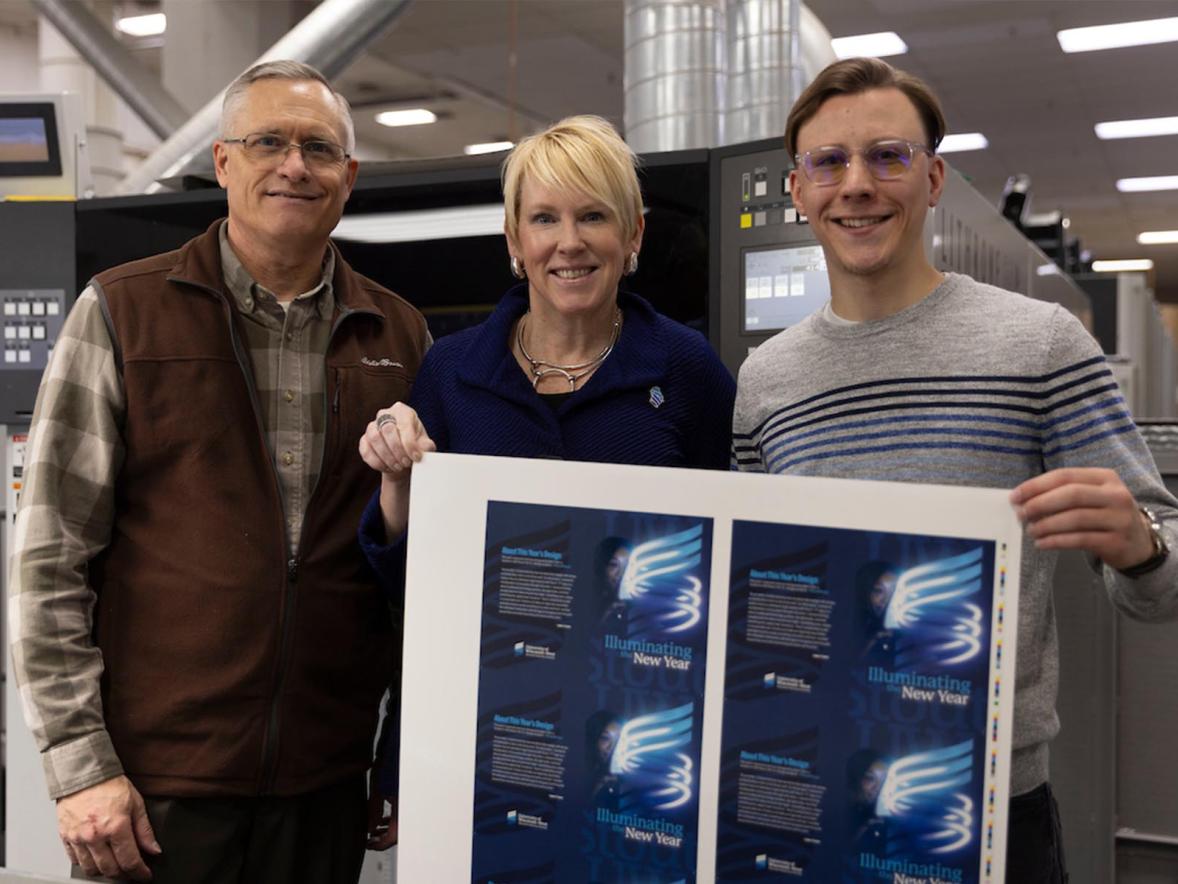

This year, the UW-Stout Phoenix Challenge Competition (PCC) team worked with Taylor Communications. The team collaborated with Label Works and Precision Press on design, prepress, production, customer service, and project management.

"As Graphic Communication students who are excited about flexographic printing and entering the industry soon, we appreciate Label Works and Precision Press team's time developing our knowledge and skills," said Bridget Johnson, PCC Team Leader.

“This is my second year working with Taylor Communications for Phoenix Challenge, and yet again it was a phenomenal experience," said Johnson. "Our time spent with the Label Works and Precision Press teams was a great hands-on learning opportunity for us, students, taking it a step further beyond the classroom. I specifically spent my time for our press run at Precision Press to produce our laminate pouch and pastry bag. Seeing the solvent-less lamination process was especially interesting to me since I have never been exposed to a finishing process like that before. Matt and Tim paid great attention to detail when helping produce our products and teaching us their craft on the press, and Tony Smith was an excellent guide in mentoring us with his flexographic knowledge. Stephen Clysdale and Wayne Nicoloff have been the best mentors and very positive in encouraging us along on our journey. I am so excited to compete with our three unique products at the 2019 competition!”

2019 Phoenix Challenge College Competition

"This project and our time with Taylor Communications has been extremely impactful," said Johnson. "We have an understanding of the scale of this project and want to thank everyone again for their dedication to our products. They look incredible and we are so excited to compete in the 2019 Phoenix Challenge College Competition! "

The team will be presenting to the Twin City Flexo Association (TCFA) on April 11 and traveling to Baton Rouge, Louisiana to compete on May 4 against other Graphic Communications students across the country.

PCC Team Testimonials

Other PCC team members also shared an appreciation for the partnership with Label Works and Precision Press, branches of Taylor Communications.

Mia Bartel

“My experience working with Label Works and Precision Press, two amazing branches of Taylor Communications, has been incredible. The passion that radiates from the people that dedicated their time to us has been contagious. A huge, special thank you to Stephen Clysdale and Wayne Nicoloff who both agreed to take UW-Stout’s PCC team under their wings for a second year. They have guided us with open arms in our team’s endeavors and we are all so very thankful. With both of their positive attitudes driving our excitement for the competition, along with Tony Smith’s flexographic expertise, our knowledge in this industry continues to grow exponentially. Also, a big thank you to Ally Handy and Calvin on the design team for mentoring me and my skill set, to understand how to grow within the creative sector of this industry. We cannot thank everyone involved enough for all the time, knowledge, and resources that were shared with us.”

Abbegail Lee

“I have learned an abundance of new information and techniques within the flexographic industry during our Phoenix Challenge College Competition project with Precision Press and Label Works. Learning about dyne levels and solvent-less lamination were two completely new and interesting concepts to me. I am extremely grateful for Stephen Clysdale, who not only guided this project from start to finish but continually pushes us to learn new things as well. Witnessing and taking part in press runs in the industry is extremely beneficial for Graphic Communications students like me, who don’t get these opportunities within our own facility. I loved watching our team’s designs come to life on the press and being a part of the problem-solving and decision-making processes. The Taylor Communications team went above and beyond to great attention to detail in the success of producing our products.”

Janessa Gould

“Personally, experiencing the press run was one of the best hands-on learning experiences I’ve had as a graphic communications student. I always read and hear about different print processes from my professors, but nothing is like seeing the real operation in front of you. It was cool to be able to apply my knowledge to the processes used to understand what was happening each step of the way. I am so thankful to the members of the Taylor Communications team for their generosity, and willingness to answer any of our questions. It is hands-on learning experiences like this that continue to strengthen my passion for print.”

Matt Smith

“My experience at Precision Press and Label Works exceeded any expectation I had. This was my first experience with a press run, and it was so exciting seeing how all of it actually comes together. Everyone was extremely helpful and willing to answer our questions. Working on the color quality was a great learning experience for me because I had never done it before, and Matt was very helpful in instructing me how to do it properly. Tim and Matt did a great job working the press with us, and Tony Smith was an excellent mentor to me throughout the day. And none of this would have been possible without Stephen Clysdale. I never felt like myself or the team was left out in the decision-making process, and the products came out looking fantastic. I am very thankful for what Precision Press and Label Works did for our team!”

A big thank you to Greg Meersman as well, for accommodating us with hotel rooms to allow the team to travel to Mankato the night before.