Packaging students from UW-Stout won first place among university teams from around the globe in the 2025 International Molded Fiber Association Student Competition.

Preston Briggs, Traverse City, Michigan; Hunter Clausen, Woodville; Lukas David, Johnson Creek; and Isaiah Sparks, St. Paul, created a sustainable packaging solution for a waffle iron, previously packaged in polystyrene, and replaced the components with molded fiber.

As modern manufacturing techniques are changing the way engineers approach their packaging designs for consumer goods, there is a growing use of molded fiber, typically seen in egg cartons and corner protectors.

UW-Stout’s team was awarded $1,000 for its first-place design. Packaging Assistant Professor Kate Liu and Briggs traveled to IMFA’s 27th Annual Conference in Miami, Florida, from April 30 to May 2, where Briggs presented a digital version of the winning design to industry professionals.

“Preston was a breath of fresh air and represented his team, his university, and himself with distinction on a global stage,” said IMFA Executive Chairman Gary Visser. “His team’s design was not only innovative but powerfully demonstrated the advantages of molded fiber compared to expanded polystyrene. IMFA believes that student engagement is essential to the future of our industry, and we’re committed to deepening our relationships with packaging programs and the next generation of leaders who will shape the future of sustainable packaging.”

Liu served as the team's advisor. She thinks their "final design solution closely reveals real-world applications and effectively addresses the initial challenge. The two factors, learned through their hands-on coursework and internship experiences, that contributed to their success were Lukas's excellent leadership and the solid design skill sets from Lukas and Preston, the team's primary designer."

IMFA’s mission is to promote environmentally sustainable packaging solutions. It is dedicated to promoting the global use of renewable, recycled and natural fiber for products and packaging. IMFA covered all expenses for Liu and Briggs, including conference registration, flights, hotel and meals.

Designing sustainable packaging

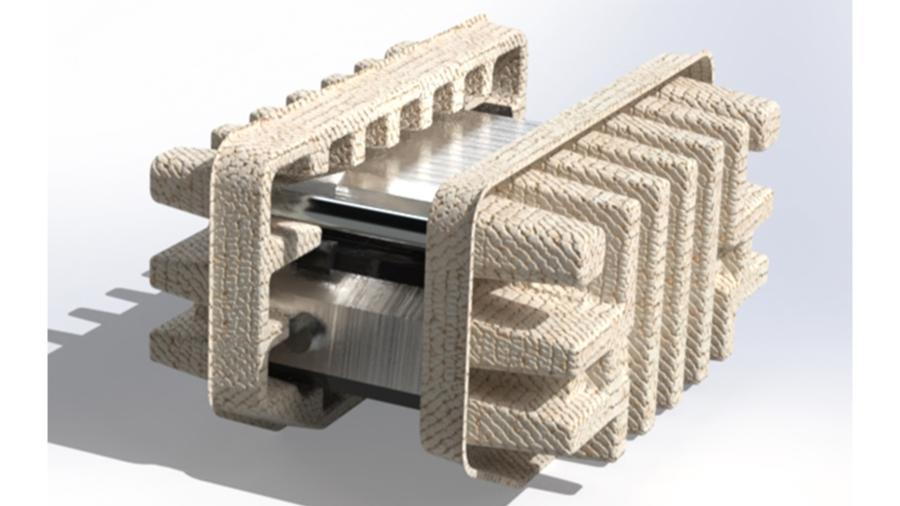

The team’s design process began with analysis and market research of current packaging, before selecting to improve the waffle iron’s packaging, which originally contained foam molds that held the waffle iron in place.

“We also saw a way to change the box dimensions to save on corrugated for shipping size, as well as shipping costs,” David said. The team considered various solutions for design improvement, factoring in stacking capacity and the consumers’ unboxing experience.

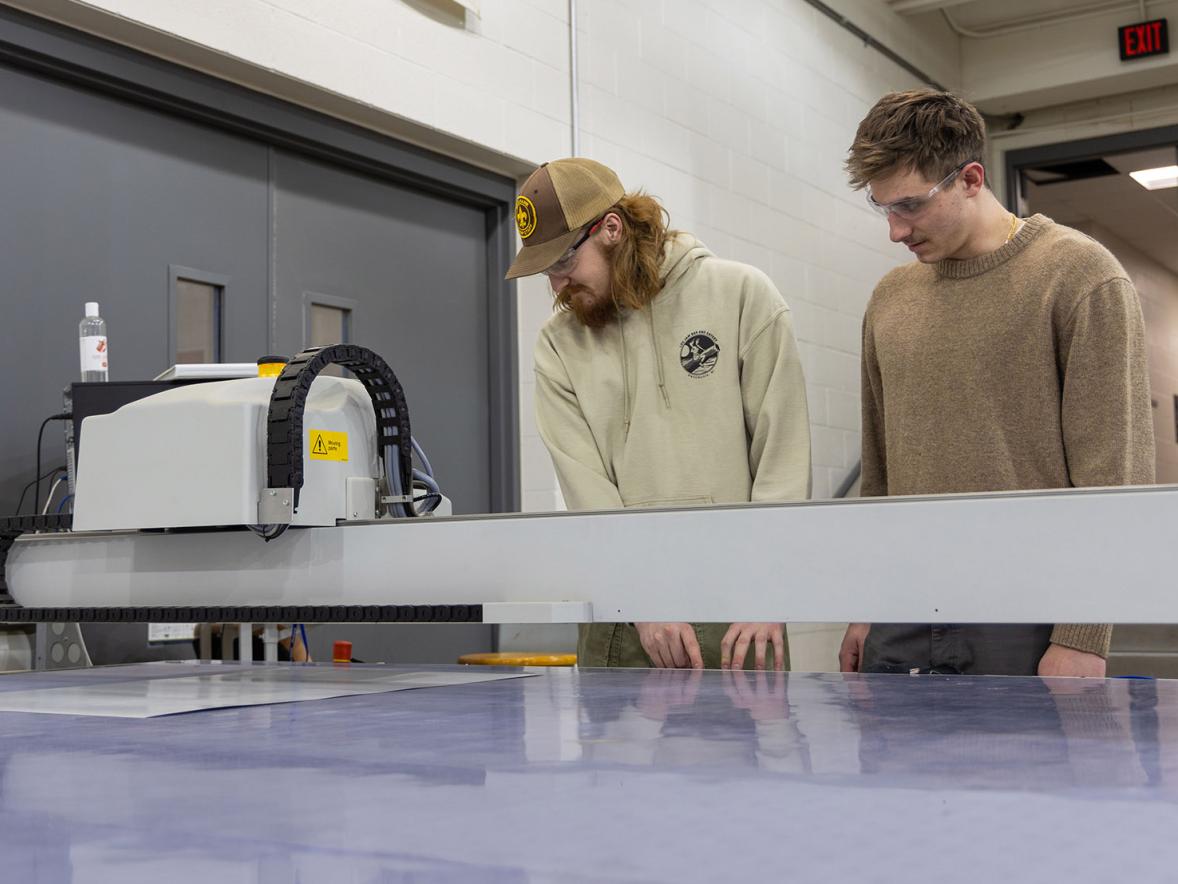

They replicated the waffle iron three-dimensionally to get a feel for what a new package could look like and worked with engineers at Milwaukee-based Keiding, Inc., a molded pulp packaging manufacturer, to ensure they were making the mold properly for use in the manufacturing environment, David said.

Briggs, Clausen and David graduated in December 2024. Briggs is working at Imagine, in Minneapolis; Clausen at Boston Scientific; and David at Sartori Cheese, in Plymouth, Minnesota. Sparks graduated in May.

“I’m very proud of our students. They did an excellent job creating the new packaging. The design showcased the students' advanced skill sets, including 3D modeling, animation and rendering,” Liu said.

UW-Stout is one of only a few schools in the U.S., and the only school in the Universities of Wisconsin, that offers a B.S. in packaging program. “Our program effectively prepares students for their careers by offering comprehensive courses and teaching essential design skills,” Liu said. “Additionally, our co-op opportunities provide excellent learning experiences within professional environments. These significantly contribute to our students’ success in national design competitions.”

Uncanny results: Students win international challenge to imagine new packaging for Pringles

Continue ReadingThis is just one of the numerous honors UW-Stout packing students have earned recently. Students also won the 2023 IMFA Student Competition, as well as first place in a competition sponsored by Kellanova, a division of Kellogg’s, to improve the Pringles potato crisps consumer experience; a Paperboard Packaging Alliance student competition; and an Institute of Packaging Professionals’ 48HR REPACK student design competition. The Stout Packaging Association hosted Packaging Jamboree 2024, or Pack Jam, an annual student-led international three-day conference.