Faculty-student research conducted this fall in University of Wisconsin-Stout packaging labs is poised to help a Wisconsin business deliver its tasty but temperature-sensitive goods coast to coast.

Associate Professor Xiaojing “Kate” Liu of UW-Stout’s packaging program worked with Madison-based Tricky Foods to test the insulating abilities of two eco-friendly packaging options – one made of cornstarch, the other of recycled paper. The goal: To determine the best way to keep the cheese, meat and other perishables on the company’s charcuterie boards fresh while in transit.

Therese Merkel, owner of Tricky Foods, worked closely with Liu for months and is confident that the research-backed expertise that she’s received – and the custom-made packing materials she ordered based on that expertise – will help her small business break into the long-distance delivery market.

“Kate is the only reason I’m able to launch this thing so quickly,” Merkel said in an interview from her Madison office. “She has been the backbone of the entire project.”

Research will aid business expansion

Merkel started Tricky Foods in her home kitchen during the midst of the COVID-19 pandemic in 2020. Thanks to her charcuterie boards filled with sliced meats, Wisconsin cheeses, fresh and dried fruits, honey, jams, nuts, and more, the business grew rapidly, and now Merkel has a storefront and 12 employees. But her ability to continue to scale up the business collided with her inability to figure out how to safely ship her goods long distances, despite customers’ requests.

“We’ve had people asking us to ship since 2020. I thought, ‘Oh, I’ll work on it when it slows down,’ and I never got around to it,” she explained.

The route around her business roadblock began when she joined a business accelerator program operated by StartingBlock, a nonprofit regional startup hub and coworking space in Madison.

“Because Therese’s products are perishable and have a very clear aesthetic, it was clear that she needed to work with packaging experts,” said Scott Mosley, CEO of StartingBlock. “As the state’s only polytechnic and the only school to have a dedicated packaging program, it was natural to recommend that Therese contact UW-Stout.”

Merkel reached out to UW-Stout’s Office of Corporate Relations & Economic Engagement, which works to connect university resources to business, industry and community stakeholders. Seth Hudson, UW-Stout’s executive director for corporate relations and economic engagement, put her in touch with Liu.

Before partnering with Liu at UW-Stout, Merkel explained, “Nobody wanted to work with me because I’m too small at this point. I didn’t have a huge budget to pay someone to help me design something.” However, Liu was willing to collaborate, connecting frequently through video calls to ask questions and show packaging samples. Ultimately, she invited Merkel to visit UW-Stout to examine prototypes firsthand, which she did in September.

Once they settled on the optimal packaging – 1.5-inch-thick biodegradable foam insulation, which dissolves in water, wrapped in recyclable plastic and accompanied by 64- to 80-ounce cold gels – Liu helped Merkel identify vendors who could custom-make what she needed.

“I enjoyed it a lot,” Liu said of the collaboration. “(It was) especially satisfying to see the solution carried out and help Tricky Foods’ business.”

Liu said she is confident that the packaging solution will meet Merkel’s needs, and she added that part of the research results will be published in a peer-reviewed article and presented at an international packaging conference in 2026.

Merkel expects to begin test-shipping products using the new packaging this Christmas season, and she’s optimistic about the results and the impact on her business. “Next year will definitely be our biggest year ever,” she said.

Impactful undergraduate research

UW-Stout is one of only a few schools in the United States, and the only school in the Universities of Wisconsin, that offers a B.S. in packaging program.

Liu’s lab assistant for the research is Claire Le, a sophomore packaging major from Phu Quoc City, Vietnam. Le said she didn’t expect to be doing such impactful research so early in her college career. “It’s been challenging, but in the best way,” she said. “I’ve learned a lot about experimental design, budgeting, troubleshooting and presenting results professionally.”

Le said the most interesting part of the project was learning how different kinds of insulating materials behaved in cold-chain conditions. “Testing cornstarch versus fiber liners and tracking how long they keep food under 40°F feels meaningful because we’re working on something that can genuinely impact food safety,” she said.

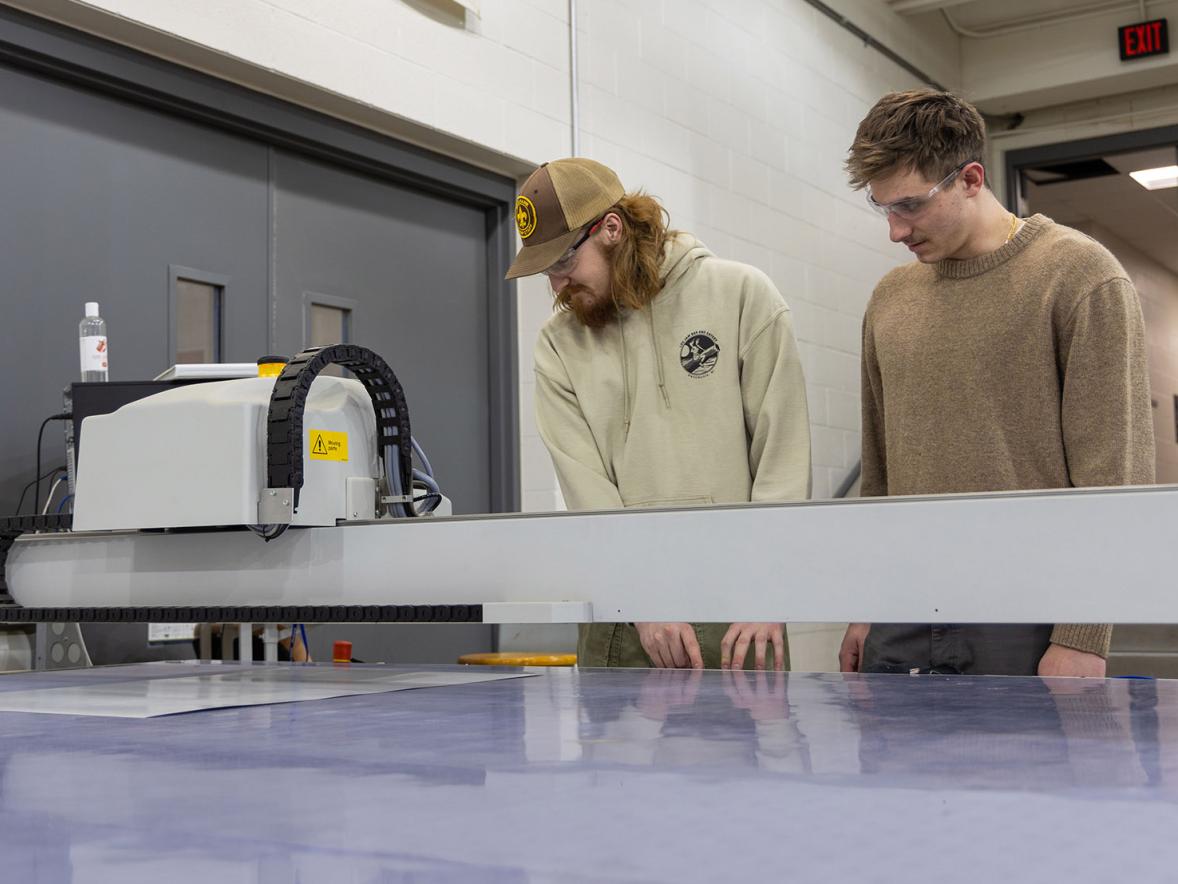

These packaging options are also more environmentally friendly, replacing products made of polystyrene foam. Repeated lab tests found that cornstarch liners, when combined with cold packs, could keep 5-pound charcuterie boards properly cooled for 48 hours. When sealed correctly, the packages maintain the necessary temperature despite vibrations during transit, which were simulated in the lab with a vibration table that jostled the packages for hours at a time.

“I hope this research gives (Tricky Foods) clear, data-driven recommendations on which insulation material is more reliable for keeping food safe during transport,” Le said. “My goal is for the results to help them make stronger packaging decisions, reduce spoilage and improve their cold-chain performance.”

Merkel called UW-Stout a “hidden treasure” because of the expert assistance it can give to businesses like hers.

“For an entrepreneur who’s new in the e-commerce game, (UW-Stout) is the difference between me being able to launch this and not,” she said. “Without Kate, I wouldn’t have been able to. I’m just beyond grateful.”