With manufacturing facilities around the globe, Prent Corporation provides custom thermoformed packaging solutions for medical devices, electronics and more for many of the world’s leading Fortune 100 companies.

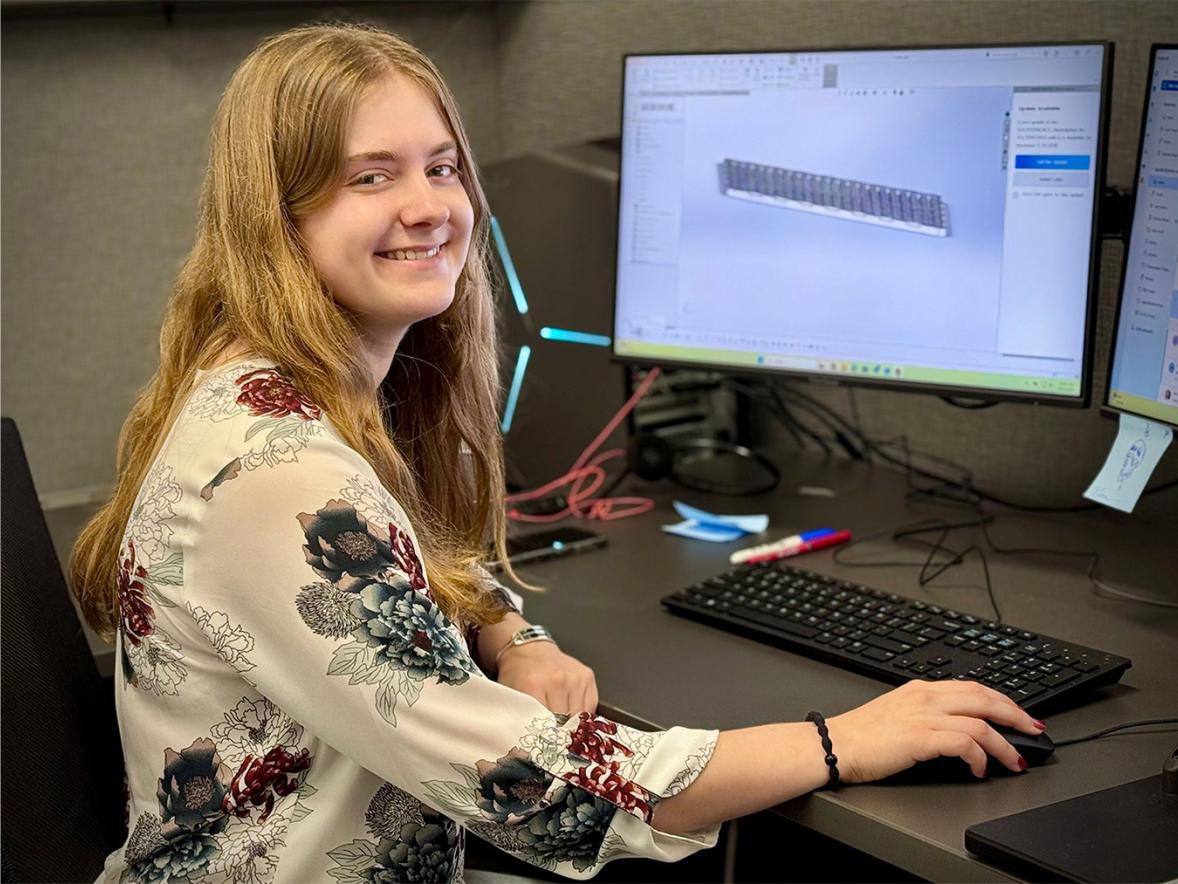

At Prent Corporation’s headquarters in Janesville, UW-Stout industrial and product design student Izabelle Quade is seeing these solutions firsthand and applying skills she’s learned to help design packaging during her product design engineering cooperative this summer and fall.

“Prent creates packages that house products that save people’s lives in the medical field. Making people’s lives better is what I strive for. From making something that someone can enjoy to something that changes their daily lives,” Quade said.

“It has been incredibly cool to see the process of packaging engineering from start to finish and all the tasks that must be done along the way.”

Quade, of Buffalo, Minnesota, also has an interaction design minor and plans to graduate in spring 2028. She would like to work in product development.

How do you hope to make an impact in your field?

Everyone needs the right tool for the job. I hope to design things that people can interact with and find satisfaction in.

No matter the industry I go into after college, I would like to make things that better people’s everyday lives. Whether it’s simply through how they feel about the products they use or how they interact with them, I want people to find use in the items that I help create.

What are your main roles as an intern with Prent Corporation?

As an addition to Prent Corporation’s product development team, I assist in designing and redesigning thermoformed packaging. Thermoforming is the act of heating up plastic and forming it within a mold.

I have worked on designs for packaging for a heart replacement valve kit and catheter kits. I’ve also helped with the organization of our tool room and am assisting in the prototype lab.

I attend team meetings and company visits, gather customer details, edit drawings and assist other departments involved in the development process.

What do you enjoy most about your internship?

I enjoy the atmosphere of Prent Corporation. Within the hustle and bustle of our busy work hours, they value their employees.

People are very connected throughout departments and communicate easily. This is helped by the fact that each building is connected, allowing people to walk over to other departments with concerns they have. They also put on events for employees. I attended a baseball game between the Beloit Sky Carp and the Cedar Rapids Kernels.

What is challenging about your internship, and how do you face those challenges?

I found communication to be hard upon starting my internship. I worked through this by asking who others were and who I should reach out to in different situations. Most people I work with directly are housed in the same building. I can walk over and ask questions in a straightforward way. This decreases the response time and leaves less room for misunderstanding.

How will your courses and experiences at Stout help you make an impact in your career?

I believe that my courses at Stout will help me achieve my goals in the future. Fashion Without Fabric stands out to me the most when I think of my learning at Stout. Like many of my courses at Stout, FWOF challenged me to think outside the box.

(FWOF is the School of Art & Design’s crowd-favorite runway show, where hundreds of 3D Design course students work in teams to create unconventional fashions.)

Solutions can be hard to find, but taking a different way to look at them is always helpful. The FWOF assignment also represented the challenges that you must get past for the final result. Working with hard materials can be compared to working with hard people, hard circumstances, or simply with yourself. Learning to understand your strengths and weaknesses is the first step toward tackling any challenge.