After collectively putting thousands of hours into their capstone projects, the moment of truth arrived in May for seniors in University of Wisconsin-Stout’s manufacturing engineering and mechanical engineering programs when they presented their projects to industry leaders, faculty and their peers.

The projects weren’t merely classroom exercises: For seniors in these undergraduate majors, the capstone projects involved creating working prototypes that addressed real-world challenges posed by corporate sponsors that included Cirrus Aircraft, 3M, Ashley Furniture, Nordson EDI, Realityworks, Industrial Heat Transfer and others.

These firms partner with students in UW-Stout’s Robert F. Cervenka School of Engineering to address challenges as diverse as creating a system to pressure test heat exchangers to dispensing liquid silicon rubber into manufacturing equipment, and from safely stacking factory pallets to creating an automated system to chemically coat aluminum aircraft parts.

Project called a ‘win-win’

That latter challenge, proposed by Duluth, Minnesota-based Cirrus Aircraft, was in the hard-working hands of a six-member team led in the spring semester by Gabrielle Winstead, a mechanical engineering major from Kennewick, Washington. The goal of the project was to create an automated system to chemically coat machined aircraft parts, which need to be dipped into – and removed from – nine successive tanks.

“It is super gratifying to know that what we worked on all year not only produced a successful working system but will possibly be implemented into a real company,” Winstead said.

Last fall, the student team visited the Cirrus facility to learn about the current manufacturing process, which involved an employee manually dipping the aircraft parts, a repetitive and time-consuming job.

Using the technical and communication skills they’ve gained throughout their UW-Stout careers, the capstone students got to work on a project that combined all three of the university’s polytechnic tenets – applied learning and research, business and industry collaboration, and career-focused experiences. The team faced numerous challenges, from creating a machine that could properly move the parts up and down to procuring the right motors.

“We overcame the design challenges and procurement through a lot of brainstorming and prototyping,” said Winstead, who before graduation accepted a position as a field service engineer with Applied Materials in Boise, Idaho. “Additionally, seeking feedback from professors and other knowledgeable individuals was instrumental in refining our approach.”

In addition, size became an issue: There simply wasn’t enough space in the Manufacturing, Material Removal & Metal Forming Lab in Fryklund Hall to build an apparatus with nine full-sized tanks. Instead, the team created a prototype with just two tanks that demonstrated the process using automated, mechanical and pneumatic systems.

Antonio Meyer, a mechanical engineering major from Elk Mound who was team lead during the first semester, said consistent communication, real-time problem solving and adaptability were key to overcoming the problems the team encountered.

“I learned that strong teamwork relies on trust, clear communication and flexibility,” Meyer said. “Everyone has different working styles and strengths, and it’s important to recognize and leverage those. I also learned the value of stepping up when the team needs direction but also stepping back and letting others take ownership of their parts.”

The students worked with Cirrus Manufacturing Engineering Manager Marc Wollak to provide project updates, ask questions and receive guidance.

Cirrus chose this engineering challenge because the current manual process required a technician’s undivided attention, Wollak said. Automating the process would save a large amount of time for the operator.

“The final product was well done and provided a solid solution to our problem,” Wollak said. “There will always be modifications through continuous improvements, but the Cirrus team was very excited about the solution provided and the amount of detail that was captured for the process.”

Wollak added that working with UW-Stout was a valuable experience for both the students and Cirrus Aircraft. “Stout provides some amazing and talented students thorough their program and its win-win for both sides,” he said.

“The feedback from Cirrus was incredibly valuable,” agreed Meyer who is now a design engineer at Cretex Medical in Brooklyn Park, Minnesota. “They helped us stay grounded in real-world applications, offered insights we wouldn't have considered on our own, and kept our design aligned with their operational needs. It elevated the project from a student prototype to something with industrial relevance.”

The Cirrus capstone team also included mechanical engineering majors Tyler Geisenhoff of Chisago City, Minnesota; Nick Roller, of Antigo; and Carter Zaspel, of Gordon; and manufacturing engineering major Prena Rai of Nepal.

Students face a real-life heavy lift

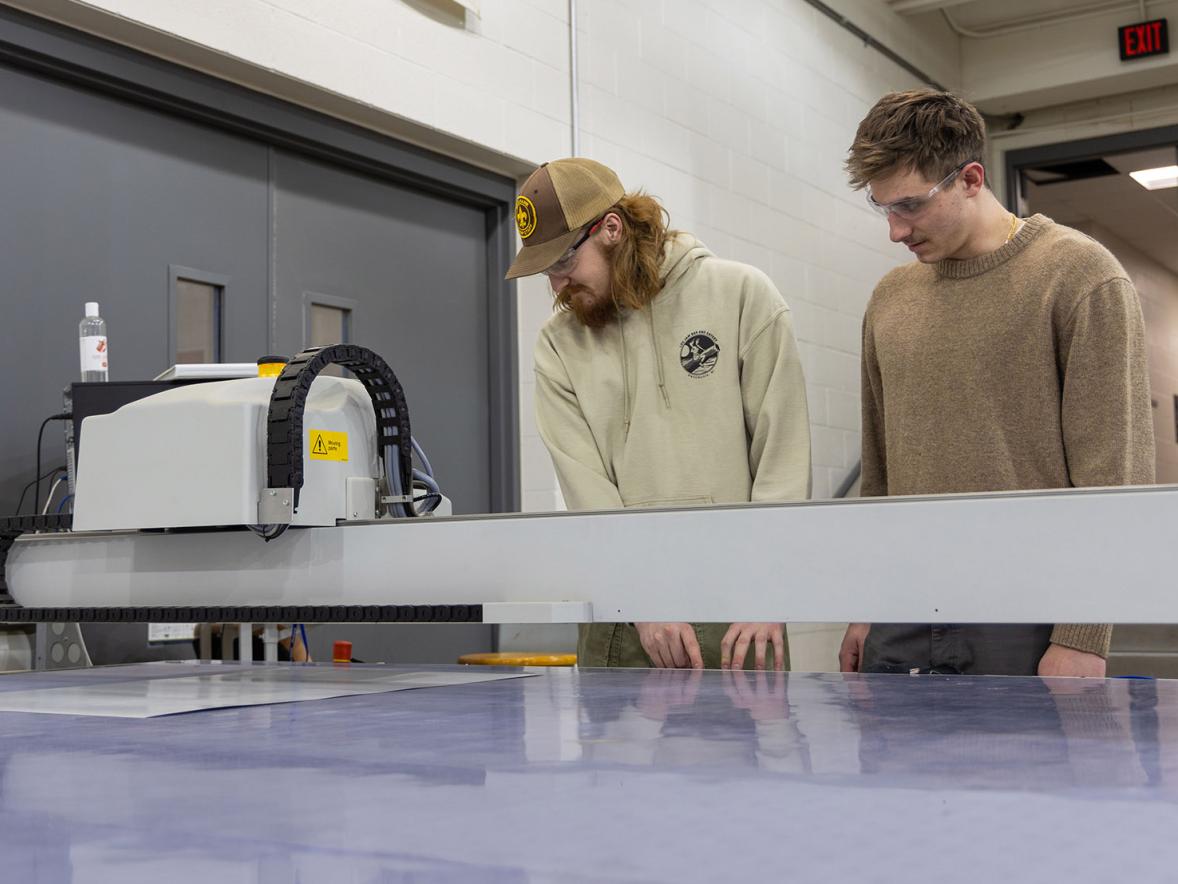

During the spring semester, the Cirrus capstone group was just one of 14 teams composed of 80 students working on projects in various stages of developing in Fryklund Hall labs.

Among the first-semester capstone teams was one tackling a project on behalf of Arcadia-based Ashley Furniture. That team was tasked with designing a device that could lift and hold 6-foot-long, 100-pound pallets off the ground until a stack of 12 was collected. The biggest challenge was the requirement that they use electrical power, rather than pneumatics or hydraulics, to lift a heavy stack of pallets in one of the company’s warehouses.

Luke Mertens, a double major in manufacturing and mechanical engineering from Easton, Minnesota, said his team overcame these challenges one at a time. “It all comes down to identifying what a functional need is of your design and then brainstorming potential design concepts that can satisfy that need,” he said. “This is a never-ending cycle. It is an unrelenting pursuit of solutions that are justifiable. A lot of it is mindset related. As a team, you must continuously tell yourselves there is a way to solve a given problem within the constraints you are operating in. Breakthroughs often come just after the moment you feel you’ve exhausted every option.”

The Ashley team also includes manufacturing engineering major Zachary Morgan of Eau Claire and mechanical engineering majors Chase Rodewald of Lake City, Minnesota, and Riley Stiehl of Alma.

The challenges that are inherent in the capstone process provided students with opportunities to learn, grow and adapt, Mertens explained. Along the way, he said, the team has been aided by input from representatives from Ashley as well as others who attended an end-of-semester presentation, which featured computer schematics and a small-scale model of what they will build in the fall semester.

“This feedback will be used to diagnose aspects of our design we need to further investigate, improve and validate,” Mertens said, adding he looks forward to presenting Ashley with a functional solution by the end of the year.

Ready to step into industrial roles

The engineering capstone classes are led by Assistant Professor Dan Bee; Assistant Professor Nathan Spike, B.S. mechanical engineering program director; Senior Lecturer Glenn Bushendorf; Lecturer Anwr Al-Baghdadi; and Instrumentation Coordinator-Instructor Paul Craig, B.S. and M.S. manufacturing program director.

Bee said the faculty view themselves as facilitators in an open-ended process where the seniors must undertake their own research and develop their own solutions.

“We’re trying to give a real experience in a safe environment and help them be ready to step into a role like that in industry,” Bee said.

Students use a project management methodology called a “stage gate process,” which includes built-in reviews at key points. Students prepare a report at the end of the first semester, which is updated during the second semester. At that time the sponsor – typically an outside business – purchases the materials the team needs to build its prototype. After their final presentations, students submit what they’ve built and the accompanying documents to the companies for potential integration into manufacturing operations or continued development.

According to the university’s most recent First Destination Report, 99% of 2023-24 graduates from the mechanical and manufacturing engineering programs reported they were either employed or continuing their education within six months, with an average starting salary was $72,000.